A robust piece of farm-fresh chicken leg sat on a pristine surface at Harvard Medical School. With skin intact and bone inside, it was precisely sliced to just crack the bone.

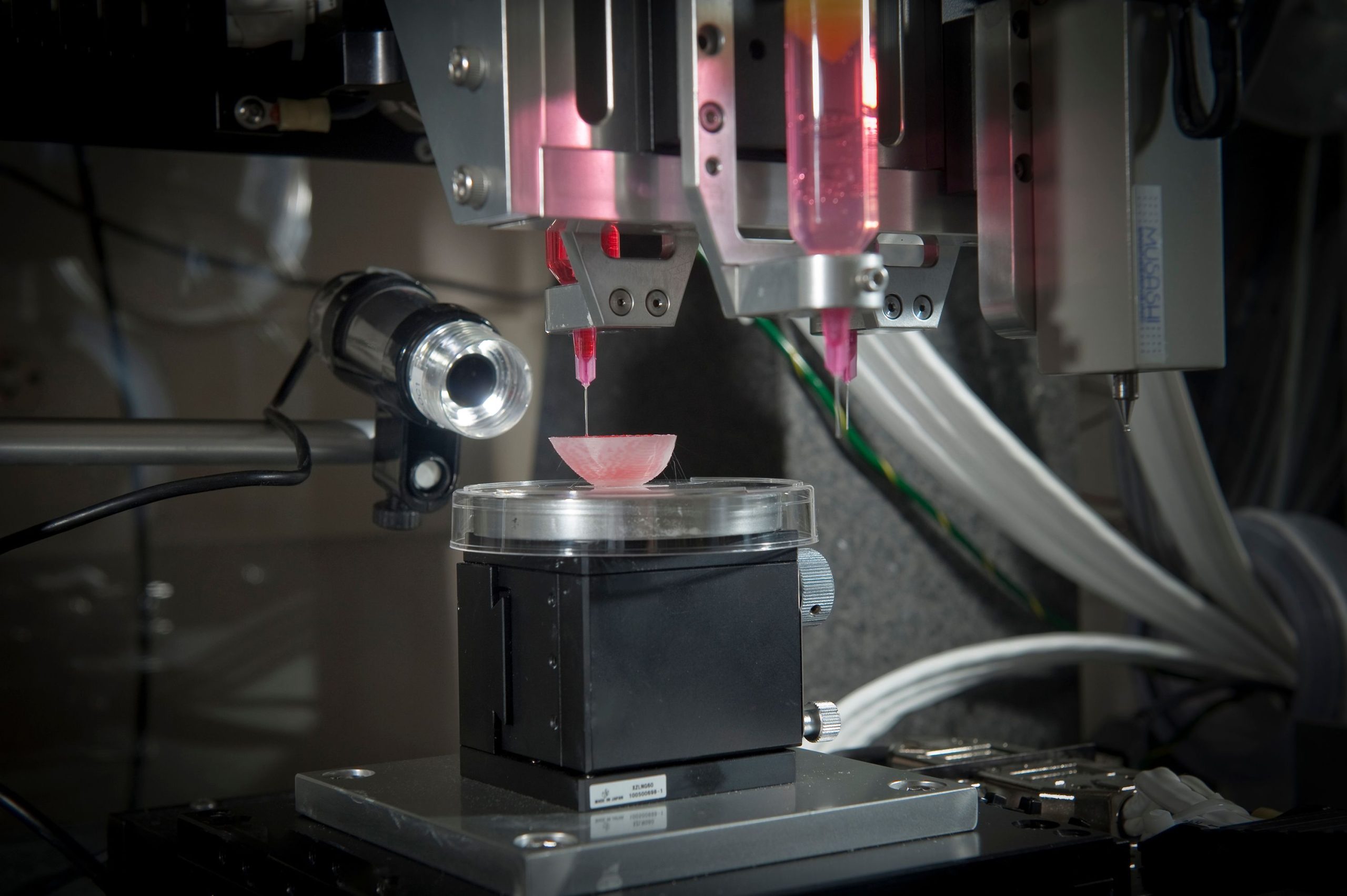

A robotic arm maneuvered over it, scanned the fracture, and delicately injected a liquid mixture of ingredients into the crack, including components isolated from seaweed.

Through several bursts of ultrasound, the liquid solidified into a substance resembling bone and sealed the fracture.

This wasn’t a cutting-edge culinary exhibition but rather an innovative experiment exploring whether ultrasound could eventually be utilized to 3D print implants directly within the human body.

Under the leadership of Dr. Yu Shrike Zhang at Brigham and Women’s Hospital and Harvard Medical School, a recent study combined the distinctive attributes of ultrasound and 3D printing to mend damaged tissue. Central to this technology is a blend of chemicals that gel in response to ultrasonic waves—a mixture known as “sono-ink.”

In one trial, the team 3D printed a whimsical bone shape inside a substantial piece of isolated pork belly, with ultrasound effectively penetrating layers of fatty tissue and skin.

The technology also crafted hive-like structures within isolated pork livers and a heart shape within kidneys.

While it may sound unconventional, the objective isn’t to 3D print emojis inside living tissue.

Instead, physicians may one day employ ultrasound and sono-ink to directly repair injured organs within the body, potentially offering an alternative to invasive surgery.

To validate their concept, the team employed sono-ink to repair a damaged area of an isolated goat heart.

Following a series of ultrasound bursts, the resulting patch solidified and seamlessly integrated with the surrounding heart tissue, essentially forming a biocompatible, flexible bandage.

In another experiment, sono-ink loaded with a chemotherapy drug was injected into a damaged liver. Within minutes, the ink released the drug into the affected areas while sparing most healthy cells nearby.

Describing the technology, Drs. Yuxing Yao and Mikhail Shapiro from the California Institute of Technology, who were not involved in the study, highlighted its potential to transform open surgeries into less invasive treatments.

They also suggested applications such as creating body-machine interfaces responsive to ultrasound, developing flexible electronics for heart injuries, or delivering anti-cancer medications directly to surgical sites to minimize side effects.

“We’re still a long way from implementing this tool in clinical settings, but these tests reaffirm the technology’s potential,” remarked Zhang. “We’re eager to see where it progresses from here.”

The versatility of 3D printing has captured the imagination of bioengineers seeking to construct artificial biological components, such as stents for severe heart conditions.

Typically, the process involves iterative steps. An inkjet 3D printer, akin to those found in offices, dispenses a thin layer and uses light to “cure” it, solidifying the liquid ink.

Layer by layer, the printer constructs an entire structure. However, light can only penetrate the surface of many materials, limiting the creation of fully printed 3D structures in one go.

The new study turned to volumetric printing, where a printer directs light into a volume of liquid resin, solidifying it into the structure of the object—resulting in a complete build.

This method is faster and produces objects with smoother surfaces compared to traditional 3D printing.

Nonetheless, it faces limitations in how far light can penetrate through the ink and surrounding materials, such as skin, muscle, and other tissues.

Here’s where ultrasound comes into play. Widely recognized for its role in prenatal care, low-level ultrasound waves can penetrate opaque layers like skin or muscle harmlessly.

Known as focused ultrasound, researchers are exploring its potential to monitor and stimulate the brain and other tissues.

However, there are challenges. Sound waves distort as they travel through the abundant liquids in our bodies, potentially distorting the original design when used to 3D print structures.

Developing an acoustic 3D printer necessitated a redesign of the ink.

Initially, the team experimented with ink formulations that solidify under ultrasound.

The concoction they settled on is a blend of molecules; some solidify upon heating, while others absorb sound waves.

Within minutes of ultrasound pulses, the sono-ink transforms into a gel.

As Yao and Shapiro explained, the process is self-propagating. Ultrasound triggers a chemical reaction that generates heat, which the gel absorbs, accelerating the cycle.

Since a robotic arm controls the ultrasound source, it can focus sound waves to a resolution of one millimeter—slightly thicker than an average credit card.

The team tested various sono-ink formulations and 3D printed simple structures, such as a multi-colored three-piece gear and glow-in-the-dark designs resembling blood vessels.

This experimentation helped the team explore system limits and potential applications; for instance, a fluorescent 3D-printed implant could be easier to track inside the body.

Next, the team turned to isolated organs.

In one trial, they injected sono-ink into a damaged goat heart—an ailment similar in humans could lead to fatal blood clots or heart attacks, often treated with open-heart surgery.

Here, the team delivered sono-ink directly into the goat heart through blood vessels. With precise ultrasound pulses, the ink gelled to protect the damaged area, seamlessly integrating with the heart’s own tissues without causing harm to neighboring areas.

In another experiment, they injected the ink into a fractured chicken leg bone and reconstructed the bone “with seamless bonding to the native parts,” according to the authors.

In a third scenario, they incorporated doxorubicin—a chemotherapy drug commonly used for breast cancer treatment—into the sono-ink and administered it into damaged sections of a pork liver.

With ultrasound bursts, the ink settled into the damaged regions and gradually released the drug over the following week. The team believes this approach could enhance cancer treatment post-tumor removal surgery.

While the system shows promise, sono-ink has yet to undergo testing inside a living organism, raising potential concerns about toxicity.

Moreover, although ultrasound is generally safe, its use can elevate sound wave pressure and heat tissues to temperatures as high as 158 degrees Fahrenheit.

According to Yao and Shapiro, addressing these challenges will guide the technology’s development.

The capability to swiftly print soft 3D materials opens avenues for creating new body-machine interfaces.

Patches for organs with embedded electronics could support long-term care for individuals with chronic heart disease.

Ultrasound might also stimulate tissue regeneration in deeper body parts without requiring invasive surgery.

Beyond biomedical applications, sono-ink could make waves in everyday life.

Already, 3D-printed shoes have entered the market, suggesting that “the future running shoes could be printed using the same acoustic method used for bone repairs,” Yao and Shapiro concluded.